- Home

- News & Events->LED encapsulation device junction temperature test this chip

At present, the LED is its excellent electro-optic conversion efficiency and photosynthetic efficiency recognized by the industry.But we all know that the LED besides its function of labor - luminescence,One must not neglect important issues,Is the fever of LED.After a dozen years of development,Although now LED electro-optic conversion efficiency has reached 40% ~ 60%,But there are a lot of energy is through the form of heat.Although people can directly by wishful thinking to source all the electric energy into light energy radiation,Want to put the excess heat,But the male and female servants do not!

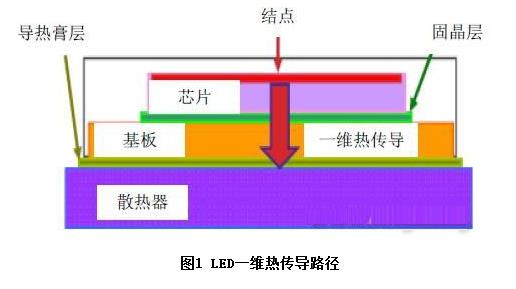

First of all, on the packaging of it,At present, the development of the LED pattern and the development of electronic packaging,The difference is the functional electronic chips for the glow LED chips,And changed his opaque packaging plastic for the pervious to light material such as silica gel or epoxy resin.So you can find,From this encapsulation

routines LED heat conduction path is also consistent with most of the patch type electronic components,Can be simplified as from chip to the substrate of one-dimensional heat path.

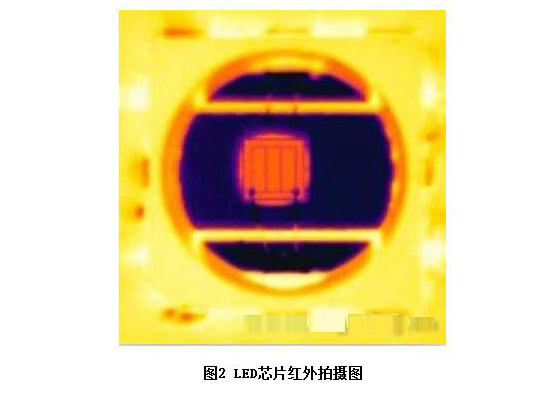

LED the fever mainly comes from its chips,Now that the fever causes a compound is the radiation from the carrier,The second is from carrier compound emitted photons and failed to effectively.If the chip is solid crystal on the scaffold,There is no lens or fluorescent plastic cover,At that time is can through infrared thermal imager to observe surface temperature of the chip.Usually this kind of situation can be achieved by infrared photograph of the chip's surface temperature.It is important to note that,On the surface of the light-emitting surface temperature can't use a thermocouple to measure.Although the thermocouple thermometer is very convenient,But for a LED chip is both light and heat,Thermocouple can because absorption of optical radiation to produce considerable error,The closer the shiny surface,The temperature of the thermocouple measurement error.

But our problem is,If it is already good chip,How can we measure chip junction temperature?It says the infrared thermal imager can only measure the object surface, with the exception of infrared transmittance strong material temperature,Not captured by lens or fluorescent glue under the cover of the chip junction temperature.

In fact,LED because of the particularity of the diode,Itself can be as a characterization of temperature sensor.It is said that the standard JESD51-1,Voltage of the diode will changes over the temperature of the p-n junction,And terminal voltage and junction temperature is very close to the linear change!Since it is,Then we can not use voltage to monitor the chip internal PN junction temperature?In fact JESD51-1 is introduced this method is feasible and accurate.

Here we simply introduce JESD51-1 mentioned in the standard test methods.

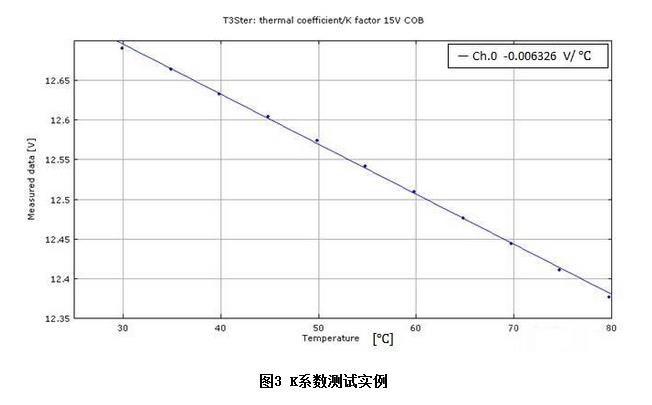

First of all, we put the above voltage - temperature variation curve of the slope?V /?T called the K coefficient of the semiconductor chip.Each chip has their own K coefficient,The decision is the p-n junction of the chip itself,Belongs to one of its own characteristics.Figure 3 for the K coefficient test instance.

K coefficient is measured in small test current Isssss (such as 1 ma) read the voltage value under different ambient temperature,And as long as give enough time,And as long as give enough time, we can think of the chip actual temperature is equal to its environmental temperature.The test current Isssss why use small current?Because the large current,Electric current will cause the fever of the chip,Chip fever after the actual temperature and environmental temperature have bigger difference,

Depending on a parameter and environmental temperature is that we can control,So our test current Isssss small current.

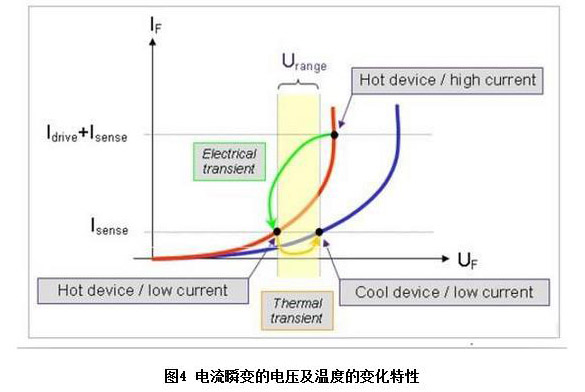

After get the K factor is the junction temperature is knowns?Since have the corresponding relation of voltage and temperature,That we can not read the LED working voltage,To push onto the chip junction temperature?But things are not so simple (unless your home LED is on small electric work shed like 1 ma ~).In the case of single chip LED,The normal work of current Idddds now has reached several hundred milliampere,Even more than 1 A,We want to know is the LED electric flow junction temperature in this work.So what should I do?Given the coefficient K,Then we can use a jump method to test?

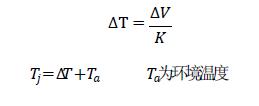

For example,The LED light under the current Idddds work for a period of time,Think the LED heat balance later,The working current Isssss suddenly jump into the test current,As long as the current jump time fast enough,As long as the acquisition speed can keep up with the voltage,And test accuracy is Kevin,We can jump into a test current is measured after the instantaneous voltage V1.In order to put the K factor,We let the LED to work in the electrical test flow until temperature thermal equilibrium with the environment,At this time to measure a voltage V2.Because the two voltage values are with Isssss measured,Then the two voltage can use K coefficient to the corresponding temperature,With the change of the two voltage value?V divided by K value can get a temperature change?T.

Clever readers can find,The temperature value?T is the environment temperature and junction temperature difference,So only need to take?T with environment temperature chip junction temperature can be calculated out.Because the acquisition time short enough,Short enough to don't believe that time hot melted away at once,Measured the first voltage value of the corresponding temperature can be thought of as the LED power down the corresponding temperature value at work.JESD51-1 standard is introduced inside this method,There is a strict proof,The author here is simply to describe the test method.

The question,Given the advanced test method,The equipment can meet the requirements of the switch with high speed and high precision?Of course there are,JEDEC committees in the standard setters is specially made a set of completely accords with the standard test equipment,That is the T3Ste is well known in the industry (r thermal transient tester ThermalTransientTester),Diodes, transistors, field effect tube or IGBT,These "moderate thermal resistance of semiconductor devices are available T3ster measurements.And after mathematical operations can also be put on the heat transfer path of each layer of the structure of the thermal resistance analysis, find out the cooling bottlenecks.